New!! Demonstration Video |

We had many requests

for a shorter version of our Installation Training Video and it

is now here!

This 6 minute "Demonstration Video"

summarizes the features and benefits of Quad-Lock's Insulating

Concrete Forms and goes over the system components and basic

steps of building with Quad-Lock ICF. This video also describes

special design elements including angles, t-walls, radius walls,

pilasters, interior & exterior finishes, etc., as well as

Quad-Deck and Green Roofs.

The Demonstration Video has no

narration so is perfect for Trade Shows.

View & download this video. |

Commercial Development Featured in ICF Builder Magazine |

|

The flagship of sustainable design in

the Baja - La Concha Pearl - was recently featured in ICF

Builder magazine.

The seven-story luxury condominium

development is getting much publicity lately for its innovative

and environmentally conscious building methods and has been

submitted to the USGBC for LEED Gold Certification.

Quad-Lock ICFs were used for the

60,000+ sqft of exterior and interior walls with Quad-Deck used

in the 82,000 sqft of floors. With a building size of over

84,000 sqft and 7-storeys, this is the largest, complete ICF

building envelope to date.

Read the article

about this development or browse the

ICF Builder magazine's profiles.

Reprinted with permission from

www.icfmag.com |

DOE Study - Retrofits are Cost Effective |

|

The US Department of Energy (DOE) recently commissioned a

study analyzing the life-cycle of two retrofit options for a

research library. The study found that the more expensive

retrofit not only exceeded the 30% energy reduction but was also

16% more cost-effective than the less expensive option (over a

40-year period) and 12% more cost-effective than making no

changes to the building.

Read the complete article in Environmental Building News.

This study validates the benefits of retrofitting existing

buildings. Quad-Lock's R-ETRO Insulation System is the perfect

solution for insulating the interior or exterior of existing

buildings.

To learn more about the R-ETRO Insulation System go to

www.r-etro.com. |

Quad-Deck Residential Tilt-Up Project |

A residential tilt-up project using

Quad-Deck is going strong in the interior of British Columbia.

Held up initially by the weather, this project is now getting

"off the ground".

Nestled on a ridge overlooking the lake in beautiful Vernon,

BC, this unique residence will be completed by end of summer

2009.

Watch for the detailed Project Profile

once this project is completed. |

Introduction to ICFs Webinars |

Quad-Lock's Introduction to ICFs Webinars

are still going strong.

See the complete schedule & register!

"The goal of these webinars is really

education" says DJ, Quad-Lock's Eastern North America Sales

Director. "There is a lot of mis-information out there. Really

all we are trying to do is be helpful to people who are

interested in this building technology - if it helps sell

Quad-Lock, that's great; but the real benefit is boosting the

ICF industry."

During these 1-hour presentations, attendees will

gain:

A basic understanding of ICF

A basic understanding of ICF

An understanding of the types

of structures you can build with ICF

An understanding of the types

of structures you can build with ICF

Knowledge to make a more

informed buying decision

Knowledge to make a more

informed buying decision

Insight into the Quad-Lock difference

Insight into the Quad-Lock difference

Reserve your seat in one of these upcoming webinars. |

|

Quad-Lock is Committed to the Environment

|

The economy is still slow, which gives all of us time to take a

thorough look at our businesses, make improvements and get ready for the

better times ahead.

We at Quad-Lock Building Systems, do not only want to sell a "green"

building material, we want to be and live "green". We believe that this

strongly distinguishes us from our competitors, not only in the ICF and

insulation industries, but in the whole building materials industry.

In order to be and live "green", we have utilized the

past months to work towards the following goals:

ISO-14001 Certification: ISO-14001 is

the internationally recognized environmental management

system standard. It provides a framework to manage the prevention of

pollution. We are planning to certify Quad-Lock Building Systems to this

standard in the early part of summer 2009. We will be the only company

in the ICF industry (and one of the very few in the building materials

industry) to do so.

Emissions reduction: We are actively

working towards reducing our emissions to the lowest levels possible by

doing energy audits on our equipment and implementing the commendations

made.

Scrap reduction: We are working hard at

reducing our scrap to even lower levels than what we have accomplished

already. A reduction in scrap not only means fewer product that has to

be reworked/recycled, but also more product that we can sell.

Minimize garbage: We are trying to

minimize the garbage going to the dumps from our plants. We are doing

this by recycling our and other's EPS scrap, and by recycling metals,

other plastics and paper.

By working on all of the above goals, we will not only improve our

environment, but we will also save energy and money.

And that is also what our products and services are all about: save

energy and money for our customers and reduce our customers' impact on

the environment. We do that by offering you the Quad-Lock wall systems

with R-Values up to R-38, the Quad-Deck floor/roof systems with R-Values

of up to R-33, and the R-ETRO insulation system with an R-Value of R-18.

Thank you for your continued support in these hard times. We do

appreciate your loyalty.

Best regards,

Hubert Max Kustermann, CEO

What's So Green About ICFs? Part II

|

In the January 2009 installment of "What's So Green About ICFs?", we

talked about Energy Conservation and Carbon Footprint Reduction. The

main point was that to reduce the life-cycle cost of the building and

reduce the carbon footprint, the biggest impact was gained by

controlling the building's appetite for energy and reducing energy use

during the operational phase of the building's life, where 90% of the

total energy use is centered.

In this issue, let's take a look at how to minimize material

consumption in the building shell, and at opportunities for on-site

recycling of materials.

Minimize Concrete and Steel Consumption: As pointed out in the last

issue, one of the biggest detractors from thermal performance in the

building envelope is uncontrolled air leakage, or convection. Concrete

walls offer a 100% effective air barrier, which studies have shown to

reduce building air infiltration rates as much as 60%, with no

extraordinary measures taken around windows and doors. (Source- CMHC

"Monitored Thermal Performance of ICF Walls in MURBs" Dec-2007)

Whether the concrete is 12" [300mm] thick or 4" [100mm] thick, it

will still act as an air barrier. In addition, concrete has very little

R-Value, in fact almost negligible. Consequently, "more" is not

necessarily "better". Unless there is some compelling reason to use

thicker concrete walls, the minimum wall section size should be used in

the building envelope design. Structural factors like seismic and wind

loading should govern the selection of concrete wall thickness.

Quad-Lock offers wall cavities as small as 3.75" [96mm], and the

Quad-Lock, high density, EPS panels provide the same insulation values

for all cavity sizes

Steel Fibers: Steel consumption can be minimized in many instances by

employing steel fibers in the ICF concrete mix as a replacement for

rebar. Steel fiber technology has made tremendous gains in the past few

years and Quad-Lock customers have saved tens of thousands of dollars by

substituting steel fibers for conventional reinforcing bar. The

corresponding net reduction in the steel required makes this option very

attractive from the 'green' point of view.

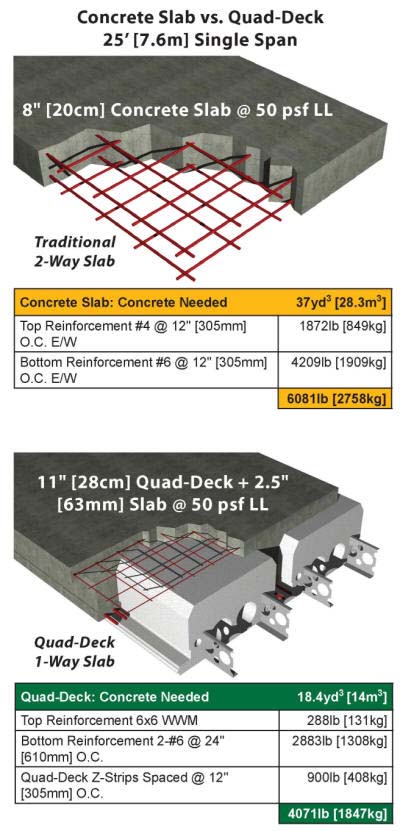

Quad-Deck: Recently, Quad-Lock had a structural engineer compare the

material consumption in a conventional two-way slab versus a Quad-Deck

'one-way' slab design for a similar structure. The calculation revealed

a 33% reduction in steel consumption and a 50% reduction in concrete

usage for the same span and loading conditions by the Quad-Deck

structure. Additionally, supporting elements would be of a much smaller

size due to the lighter weight of the Quad-Deck T-beam structure.

A graphic illustration of this calculation follows:

Waste Reduction: Another way to

'green' a Quad-Lock project is to minimize waste generation. One of the

greenest features of the Quad-Lock system is the ability to utilize

panel off-cuts from the construction process. First, any piece of

Quad-Lock panel that will fit between two ties can be used without

danger of blow-out. As long as the seams fall between the two tie

flanges of any tie, there is no danger. Workers need to develop the

habit of looking first to the scrap pile when cutting panels. Mid-way

through the installation, any piece of panel that can be cut to a

multiple of 12" [300mm] should be prepared and used in the job.

Second, 10" [254mm] and even 8" [203mm] pieces of panel should be

grouped and saved to serve as in-fill pieces at seams or near doors and

windows, when a full panel doesn't quite reach. They can also be made

into end-caps and used with Quad-Lock Window Brackets to terminate a

wall.

Third, even the smallest panel pieces can be recycled on-site and

used as insulation/protection over buried utility lines, like water and

electrical supply lines. Under-slab insulation is another excellent use

for panel scrap.

Cut ties should be collected and the tie flanges salvaged for use in

corner and T-wall construction. Any leftover tie material can be

recycled at most community recycling centers as 'HDPE', category 2.

Quad-Lock packaging should be used for jobsite clean-up, and later

recycled. Quad-Lock plastic bags are "LDPE", category 4.

Tie boxes are recycled as "corrugated cardboard".

You can find resources for 'greening' your project on the Quad-Lock

web site. Look for

Technical Bulletin 1.90 on Best Material Utilization Practices and

Quad-Lock's "Green

Checklist" for design professionals and builders.

Call the Quad-Lock Training and Technical Services department for

more information about steel fibers.

Douglas Bennion

Going Beyond the Block II

|

Dealer Sales & Product Supply

How frustrating is it to think of a couple more important items,

AFTER you've hit the "print" button? That's what happened with our last

installment of Beyond the Block that focused on total project solutions

for foundations. Therefore, here are a few more points to consider when

talking about total project solutions:

- Get the project off to a good solid start by doing some planning

and prep work. Recognizing the fact that your ICF work is only a

portion of the complete job will give the customer confidence in the

fact that you are a real team player with THEIR best interests in

mind.

- Look over the ENTIRE project before you start. Have a good

understanding of the big picture, including the scope and timing for

the various phases of work, especially where YOUR part fits. Think

through the timeline for your project and line up supplies,

laborers, inspections, etc., so the project isn't stalled by poor

planning.

- Meet and coordinate with the excavator before digging starts and

stay in touch as the excavation proceeds. Dig only where needed and

don't over-excavate!

- Take the time to set batter boards (Boards erected at the

corners of a proposed building to specifically locate and show

corners and foundation wall height) and strings both before

excavation and again after the footing is in place to be sure your

footer is square and level. This "extra" work in the beginning will

save re-doing, re-moving, re-setting, and re-GRETTING down the road

as your Quad-Lock walls and floors will go up much more smoothly and

quickly.

- As mentioned in the previous article, when pouring the footer

and stem wall at the same time you can eliminate one pump trip

(saves $$) and get your project ready for the first floor install

sooner (saves time). A word of caution with this method; make sure

your concrete is flowing properly into the footing forms as it may

"hang up" on the support member at the top of the footing and cause

your wall to sag. Refer to pages 57/58 of the Quad-Lock manual and

follow the monolithic pour diagram closely.

- An electrical ground is required for the structure. A relatively

simple solution for this nationwide electrical code requirement is

the "Ufer Rod" method that takes advantage of the conductive

properties of concrete; luckily, you will have plenty of that

available with an ICF structure! How to: run a 20-foot piece of

rebar UNDER your footing in direct contact with the soil so it can

be connected to the main electrical panel. "Google it" and learn a

little more.

John Hatfield - Regional Sales Manager, Rocky Mountain Region

Proven Energy Efficiencies

As

part of our on-going development of materials to assist in the sale of

Quad-Lock, we want to create a library of statistics about structures

built with Quad-Lock Insulating Concrete Forms. You can help us by

submitting your energy bills, along with the bills from a comparable

house in your neighborhood for us to add to our library. When you do

this Quad-Lock will pay your highest month's

energy bill for your troubles. As

part of our on-going development of materials to assist in the sale of

Quad-Lock, we want to create a library of statistics about structures

built with Quad-Lock Insulating Concrete Forms. You can help us by

submitting your energy bills, along with the bills from a comparable

house in your neighborhood for us to add to our library. When you do

this Quad-Lock will pay your highest month's

energy bill for your troubles.

Contact us for more information.

|