Sustainable Building Shell Construction |

Quad-Lock will be hosting two, 6-hour

training seminars during World of Concrete in Las Vegas,

February 5th and 6th, 2009. The seminars will be held at the

Embassy Suites Hotel.

These seminars will feature construction

techniques for:

Insulated, poured-in-place walls

Insulated, poured-in-place walls

Green roof structures

Green roof structures

Multi-story ICF construction

Multi-story ICF construction

Insulated tilt-up panels

Insulated tilt-up panels

Suspended ICF floors

Suspended ICF floors

In addition, Quad-Lock's new R-ETRO

insulation system will be introduced and time will be spent

building a strategy for your green construction or design

business.

Please

register

for one of these training sessions. |

LEED 2009 |

Jerry Yudelson, green building guru,

Principal of Yudelson Associates and also the Chair of the

steering committee for the GreenBuild Conference and Trade Show,

recently wrote an update about the first major makeover in the

past 5 years for the USGBC's LEED program - LEED 2009. You need

to know that all of the current systems disappeared on December

31, 2008... In essence, Mr. Yudelson says that it's going to be a bit

rocky at the beginning. For example, contracts for the required

400-page "Reference Guides" that will help you understand the

bare-bones language of the new standards (which are available on

the

USGBC website) have just been awarded, with a delivery date

of Summer 2009. That means it will be hard to know exactly where

you stand with a given project, until that time.

In addition, the LEED Accredited Professional (LEED AP) exam,

which tests potential assessors' credentials, is also shut down

as of December, for an undetermined period of time, while a new

test is created, vetted and rolled out.

The USGBC is transitioning its document review and

certification from a handful of contract 'review teams' to ten

ISO-type certification oversight organizations, which in turn

will accredit individual assessors. The method for becoming an

assessor has not yet been set up.

So, if your project was not registered prior to December 31,

2008 be warned that you'll probably need extra budget to handle

the transition period and resultant confusion that will likely

persist well into 2009.

|

Introduction to ICFs Webinars |

|

There are lots of people out there who have questions about

insulating concrete forms. To aid in demystifying ICF, every two

weeks DJ Ketelhut is hosting an online webinar introducing

insulating concrete forms. "The goal of these webinars is

really education" says DJ, Quad-Lock's Eastern North America

Sales Director. "There is a lot of mis-information out there. Really all we are trying to do

is be helpful to people who are interested in this building

technology - if it helps sell Quad-Lock, that's great; but the

real benefit is boosting the ICF industry."

During these 1-hour presentations, attendees will gain:

A basic understanding of ICF

A basic understanding of ICF

An understanding of the types of

structures you can build with ICF

An understanding of the types of

structures you can build with ICF

Knowledge to make a more

informed buying decision

Knowledge to make a more

informed buying decision

Insight into the Quad-Lock difference

Insight into the Quad-Lock difference

Reserve your seat in

one of these upcoming webinars.

|

New Project Summary |

The

Kalamath Millshops in Denver, Colorado

was a challenging 2-story, multi-use project. Transitioning from

a 12" wide 3' tall footing to a 6" wide brick-faced wall that

rises 2 stories was easy compared to the orchestration of

materials and crews in an incredibly compact site.

Read the summary on this project. If you

have any further questions about this project, you can

contact

John Hatfield, Regional Sales Manager for the Rocky Mountain

Region. |

Ten Best Green Jobs |

Fast Company recently released an article describing the 10 best

green jobs for the next decade. No surprise that Energy

Efficient Builders came in at number 4! Here's what they said:

Buildings account for up to 48 percent of US energy use and

greenhouse gas emissions. LEED, the major green building

certification, has over 43,000 accredited professionals. But the

cutting edge in efficient buildings goes far beyond LEED.

Buildings constructed according to Passivhaus and MINERGIE-P

standards in Germany and Switzerland, respectively, use between

75% and 95% less heat energy than a similar building constructed

to the latest codes in the US. Greening the US building stock

will take not only skilled architects and engineers, but a

workforce of retrofitters who can use products to massively

improve the R-Value (thermal resistance) of the draftiest old

houses. A study by the Apollo Alliance recommended an $89.9

billion investment in financing to create 827,260 jobs in green

buildings -- an initiative supported by the Obama stimulus

package, which specifically mentions energy retrofits. |

January is National Radon Action Month |

The EPA has declared January National

Radon Action Month.

Radon is the second leading cause of lung cancer in America

and the leading cause of lung cancer among non-smokers.

Radon comes from the natural decay of uranium that is found

in nearly all soils. It typically moves up into the home through

cracks and other holes in the foundation and it can be present

in any home.

Unaware of the dangers, many homebuyers skip the radon test.

Few know about radon-resistant measures, which can be installed

for very little extra money or effort. With those measures

already in place, homeowners can test for radon a month or two

after they move in, when elevated radon levels would be

detectable. If unsafe levels exist, the radon can be easily and

inexpensively remediated.

Glen Salas has written an in-depth article: 'What Home

Builders Should Know About Radon', which is available on the

housingzone website. |

|

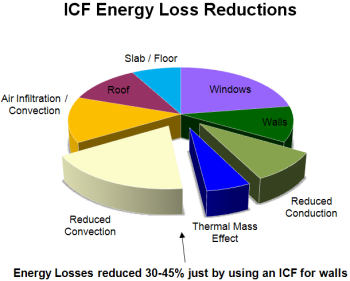

What's So Green About ICFs?

|

Whether it is from the point of view of design or construction in

the field, there is little doubt in any of our minds that green building

designs are a part of our future in the building industry. Because they

offer so many advantages, insulating concrete forms are increasingly the

logical choice for any sustainable building envelope design. But why?

What is so green about ICFs?

As long as you are involved with ICFs you will be called on to answer

this question, so we would like to bring to you a series of short,

easy-to-use explanations to help you educate customers and colleagues.

This first article starts with the 'big daddy': energy conservation...

Energy Conservation & Carbon Footprint Reduction

Life Cycle of the Building: When a life cycle analysis is done

for a built structure, the sum total of the energy consumed over its

entire lifespan, from resource extraction to construction, through the

operational lifespan and to the building's eventual decommissioning and

disposal is measured. The resulting amount of carbon released into the

atmosphere can then be calculated, along with waste destined for

landfills. The fact is the operational phase, or that time when the

building is occupied, is when it generates the most carbon emissions.

Typically, the building's occupants are using huge amounts of energy to

heat, cool, light and operate the building (whether commercial or

residential). In fact, 90% of the total energy consumed by a building

during its life cycle is during this operational phase.

The Short Answer - Conduction & Convection: The key to saving

energy and therefore carbon emissions, is to maximize the performance of

the building shell. By reducing thermal conduction through shell

components and by reducing the amount of uncontrolled air leakage

(convection) in and out of the building, you can minimize energy

consumption.

Conduction: While second to uncontrolled air leakage,

conduction of heat through building shell components has a significant

effect on the energy efficiency of every building. This is where heat is

physically carried into or out of conditioned spaces by the building

components themselves. An example of this is a wood- or metal-framed

structure. The wood or metal framing elements that span across the wall

section have an R-Value of less than R-7 and provide what is termed a

'thermal bridge'; this transports heat in an undesirable manner. When

the surface area of such framing elements is calculated and added to the

surface area of window and door openings (R-Values usually less than

R-4), it becomes apparent that 30 - 50% of the building shell is below

the assumed R-Value of the insulation and is unavailable for insulation.

When the overall insulating capacity of the shell is considered, it

falls far short in its ability to resist thermal conduction.

An ICF structure, by its very nature, eliminates heat transfer via

conduction for two reasons. First, two continuous planes of high R-Value

insulation protect the structural component (reinforced concrete) from

the effects of the outside environment, hot or cold. Quad-Lock, with its

ability to unbalance the insulation to the exterior, offers the best

protection from the elements. In laboratory tests of Quad-Lock's R-30

configuration, it took 11 days for opposing sides of the wall to become

equal in temperature. According to the testing staff, a framed

structure, wood or metal, would take a matter of hours to equalize. The

high mass of the concrete takes a large amount of energy to heat or cool

the mass and the result is a 'buffering' effect by the concrete against

swings in outside temperature. This is commonly known as the 'thermal

mass effect'. The insulation that remains in place from ICFs further

reduces the amount of energy available to raise or lower the temperature

of the concrete structure, particularly when thicker insulation is

placed on the outside of the building.

Convection: Experts agree that the greatest enemy of building

energy efficiency is the uncontrolled flow of air into, or out of,

conditioned spaces. Blower-door testing shows older framed structures to

be leaky enough to allow a complete change of interior air between 12

and 14 times per hour (air changes per hour - ACH). Even newer

'code-built' structures will leak air at a rate of 3 - 4 ACH. ICF

buildings by comparison, show air leakage rates of 0.5 - 1.5 ACH in

identical testing. Again, by their very nature, ICF buildings control

air leakage because of the density of the concrete which is placed in

liquid form and later becomes a solid. Therefore, no spaces remain in

the wall to permit air flow when concrete is properly placed and

consolidated.

* *

Most air leakage in ICF buildings is detected around window and door

openings and at the junction of walls and roofs. Sealing measures are

easy to implement in these locations. A recent test in Canada,

established that air leakage assumptions in buildings with ICF walls

could be reduced by over 60% when calculating the required heating and

air handling equipment. Lower rates of uncontrolled air leakage will

reduce the size and cost of equipment at the time of installation and

dramatically reduce the building's appetite for energy during operation.

There it is, the secret to ICFs revealed! Whether a client is just

trying to lower his or her heating/cooling bills, or whether an

architect is designing to a LEED standard in a public building, ICFs

offer real and immediate solutions to the problem of constructing an

energy efficient building shell. Because energy usage has such an

enormous impact on the environment, energy efficiency is the main area

of focus of every sustainable building program.

* Source: Portland Cement Association

Technology Briefs

Next Issue: Find out the impact ICFs and concrete can have

on how much material it takes to build a structure and how that plays

into green building standards.

Happy New Year to everyone! It is amazing to see how fast a year can

go by and I am sure many of you are happy to put 2008 in the past and

focus on a new start for 2009. If you have been in the building business

for any amount of time, the New Year ushers in the season of builder

shows aimed at contractors, residential and commercial builders,

developers and more.

We are excited to be involved in trade shows on a local level where

we support our distribution partners, as well as international and

national shows where we take the lead in exhibiting. These events are a

great opportunity to meet people, conduct research, compare technologies

and see what's new in the marketplace.

Are you in the group of people who have never attended a

building-related show? Well, I must say you are missing out. Trade shows

offer attendees a chance to engage building material suppliers in a

non-threatening environment. Many of the shows are large, so we strongly

suggest that you map out who you want to visit to ensure that you see

all the products and technologies that are important to you. I trust a

visit to the Quad-Lock booth will be at the top of the list though!

If you want to learn more about Quad-Lock and the benefits ICFs can

provide, I encourage you to visit us at one of the shows listed below -

or check out our website too as this list will be updated as we continue

to confirm our trade show schedule.

This year, you will get an opportunity to see some of our impressive

displays showing various details for both commercial and residential

construction. Our professional staff will be ready to answer your

questions regarding your project and you will be able to see all of our

products displayed including Quad-Lock, Quad-Deck and R-ETRO. And, I am

excited to announce that our booth has undergone a major makeover - it

will be worth the visit. We look forward to seeing you at the shows, you

will not be disappointed!

DJ Ketelhut

Sales Director, Eastern North America

If you can't make it to one of these events, be sure to sign up

for one of our webinars. Information on these can be found on the

sidebar.

As ICF becomes a more prevalent building system, North American

dealers and installers of Quad-Lock ICF need to extend their knowledge

of building techniques to comply with the Occupational Safety and Health

Administration (OSHA). In order to prepare for the upcoming inspection

and enforcement by OSHA, this and future articles will discuss various

compliance issues facing the ICF industry.

Safety By The Numbers...

The impetus for recent safety articles has been OSHA safety reviews

and OSHA publications relating on-the-job injury statistics. According

to OSHA's data gathered between October 2007 and September 2008, there

are many areas of exposure that could easily affect ICF installers. The

top five safety issues on construction jobsites are:

1) Scaffolding Citations - 7,428 violations were found on

2,892 construction sites (that is 2.57 violations per jobsite!) with

combined fines totaling $7,164,733, or an average of $964 per violation.

Ouch!

2) Fall Protection Citations - 4,729 violations on 4,364

sites, totaling $6,889,189 in fines at an average of $1,456 each.

3) Ladder Citations - 1,541 sites were found to have 2,046

violations. Fines averaging $616 each totaled $1,260,456.

4) Fall Protection Training - 1,638 violations on 1,557 sites

produced $566 average fines, totaling $928,505.

5) Manually Moved Ladders & Scaffolds - 1,587 violations and

fines of $1,390,818.

By far, the number one violation cited is scaffolding, but the number

one inspection item covers fall protection equipment and

training. In other words, OSHA inspectors look for fall protection

equipment and fall protection training more often than any other safety

issue.

All five major violation areas could easily be present at ICF

jobsites if care is not taken to consistently evaluate compliance with

OSHA regulations. The sizable financial impact of violation fines

obviously affects the economic health of the contractor, as would the

high likelihood of injury to his employees if such violations are left

uncorrected. Whether or not OSHA inspectors actually come onto your

jobsite, the potential for financial and physical damages is significant

when safety issues are neglected.

OSHA estimates that only about 50% of jobsite accidents get reported

to the local authority and less than 10% are reported as lost work

accidents. OSHA's data shows the next five categories in the "Top 10

List" of violations cover general safety, hazard communication or

signage, head protection, training on ladders and scaffolds and

electrical wiring. Obviously, all of these areas could also easily

pertain to ICF jobsites.

So, what's the bottom-line on OSHA violations? According to their own

statistics, when OSHA comes knocking, you'll probably get cited with

three violations, each one costing over $880 or a total of $2,650. That

$2,650 comes right of the PROFIT in your construction project budget!

The 'bonus' to being cited is that your jobsite is likely to be

re-inspected on a more regular basis for quite some time, raising the

probability that additional fines will be levied. The lesson here is

"handle safety issues BEFORE they become safety problems"!

So, as Red Green would say, "If the inspector doesn't find you

handsome, he'll at least find you... SAFE!" Don't get hurt out there!

Future ideas on tool safety, ladders and scaffold

placement, Material Safety Data Sheets (MSDS) and concrete placement

will follow in upcoming months. If you have any topics that you would

like to see covered, please

contact us.

Proven Energy Efficiencies

As

part of our on-going development of materials to assist in the sale of

Quad-Lock, we want to create a library of statistics about structures

built with Quad-Lock Insulating Concrete Forms. You can help us by

submitting your energy bills, along with the bills from a comparable

house in your neighborhood for us to add to our library. When you do

this Quad-Lock will pay your highest month's

energy bill for your troubles. As

part of our on-going development of materials to assist in the sale of

Quad-Lock, we want to create a library of statistics about structures

built with Quad-Lock Insulating Concrete Forms. You can help us by

submitting your energy bills, along with the bills from a comparable

house in your neighborhood for us to add to our library. When you do

this Quad-Lock will pay your highest month's

energy bill for your troubles.

Contact us for more information.

|