How to Superinsulate Your Building

As concerns about energy supplies and global warming continue to be debated, one idea remains clear: The best way to reduce overall energy use is to increase the efficieny of buildings.

As concerns about energy supplies and global warming continue to be debated, one idea remains clear: The best way to reduce overall energy use is to increase the efficieny of buildings.

Since buildings are responsible for about half of our total annual energy consumption, it only makes sense to design and build them with a lower appetite for energy in the first place. Quad-Lock Building Systems continues its tradition of leadership and innovation with the introduction of the new Extra Panel, which is designed to provide even more insulation value to concrete walls. Insulated Concrete Forms inherently are very airtight to meet any efficiency standards, but options for additional insulation have been limited in most ICFs.

Optimization of the Building Shell

Perhaps the most stringent energy efficiency standard in the world for buildings, the German Passivhaus Standard, states that only with an optimized building shell design can you achieve ultra-low energy buildings. Superinsulation of the floor, the walls and the roof, and advanced window technology are the required components. It is also important to note that this standard identifies that the insulation is best placed on the exterior of the building.

This means that not only the AMOUNT of insulation, but also its PLACEMENT have an important effect on the performance of the building shell. Building envelope experts agree that wall designs with 'balanced' layers of insulation are less effective than those featuring 'unbalanced' insulation layers. Extra Panel allows for the maximum shift of the insulation layer to the outside of the building which:

- Increases the R-Value of the continuous, unbroken layer of insulation surrounding the structure, which eliminates thermal bridging and offers added protection from the elements, and

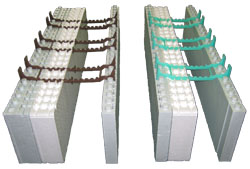

- Optimizes use of the thermal mass capacity of the concrete structure by further isolating it from extremes in exterior temperature and other weather conditions. Note examples of "TMO" (Thermal Mass Optimized) configurations in Figure 1 below.

The building shell now serves as the most effective barrier (also called a "delaying mechanism") between outside elements and the conditioned air space inside the building. The end result is far less effort required on the part of the building's HVAC system to balance the loads imposed by exterior conditions.

How It Works:

Both the concept and the application of Extra Panel are simple: The Extra Panel (R-16) is best added in one or more layers behind the exterior panel layer of any standard Quad-Lock ICF wall during construction. Depending on the desired insulating value and positioning of the insulation layer, the resulting Quad-Lock ICF wall cross-section can be any of those shown in the following:

Figure 1 - Possible Panel Configurations:

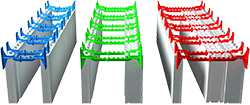

EPS Panel Configurations & R-Values

Quad-Lock panels are made of Expanded Polystyrene (EPS) with a non-HBCD fire retardant. EPS is considered to be world class insulation with qualities that makes it impervious to time and moisture. EPS is inert and chemically stable and will not emit any gases into living areas under normal use. The R-Values below were calculated per ASTM standards at 75˚F, one of the few methods allowed by advertising laws. Note that the ASHRAE Handbook allows using higher and more accurate R-Values for EPS, especially under colder conditions, in contrast to some other insulation materials that perform worse than advertised when heating or cooling is actually required. EPS is quite different from XPS (eXtruded polystyrene) and other insulation products due to its use of air as insulator and inherent long-term (50 years+) stability.

Product selection and take-offs are easiest with the Online Estimator or Excel® Estimating program.

Disclaimer: Thickness of EPS foam on the building's interior should not exceed 4¼" unless approved by a licensed engineer and building officials. Some configurations / insulation thicknesses may not be allowed by local building codes without specific approvals - see Guide to ICF Code Compliance. Notes: TMO = Thermal Mass Optimized; All stated R-Values contain R-2.66 for: inside air, ½" gypsum wallboard, 6" concrete, 5/8 T1-11 Finish and outside air.

Simple By Design:

Extra Panels are specially molded to integrate with all other Quad-Lock components, but cannot be mistaken for standard panels. Extra Panels are reversible (in all directions) to make installation fast and easy.

Longer ties accommodate the added thickness of insulation without sacrificing the cavity width for concrete. While only 5.75" concrete cavities are shown in the previous table's examples, many combinations of 'off-the-shelf' standard Quad-Lock Ties and the Quad-Lock Extender Ties are possible to create wall sizes that meet the structural requirements of the design. Quad-Lock Ties now come in 6 standard lengths and can create a range of nominal cavity sizes from 4" up to 14" (when placed in 2 Quad-Lock 2¼" Regular Panels). Quad-Lock Extender Ties each add 12" to any Standard Tie. All Quad-Lock Ties are color-coded.

Extra Panel & 90° Corners:

Corners that include Extra Panels are built in the same basic fashion as any other Quad-Lock corner, by inserting corner brackets and ties into the Regular or Plus Panels. Extra Panels can be placed in a simple lapped pattern at 90° corners.

When a 4¼" Plus Panel is used for the exterior side form, either of its two rows of tie slots can be used to position metal corner brackets and plastic ties. If the tie flanges are not required to function as anchor points for exterior finishes, we recommend that you place the Outside Corner Brackets and the Corner Ties on the inside row of tie slots (see Figure 3).

Extra Panel & Angles:

At corners other than 90° angles, the Extra Panels should be miter cut in the same fashion as Regular or Plus Panels. The angle bracket is placed on the outside layer of forms.

Track and Other Accessories:

Quad-Lock Extra Panels do not require their own metal track, as they are supported at both the interior and exterior building faces by Quad-Lock Regular and/or Plus Panels. It is only the two outboard layers of panels (Regular or Plus) that need to be contained by their respective 2¼" or 4¼" tracks at the bottom of the wall. The same is true at the top of the wall where the track is usually inverted and placed over the panels, but without Quad-Lock Wire Top Ties to connect the panels. Instead, wood or metal cleats are fashioned to fit the added width of the wall assembly, and screwed at regular 3' to 4' intervals along the track at the top of the wall. These cleats and the metal track can be removed and re-used after the pour is complete and the concrete sufficiently set.

Corner brackets, tie flanges, and overlapped track are also not necessary for Extra Panel layers, only on the 2 outer panels, similar to Quad-Lock wall installations that do not employ Extra Panels.

Technical Information:

Figure 4 - Details of Extra Panel

Quad-Lock EPS Panel Types & Densities

| Panel: Thickness | EPS Board Types | Nominal Density |

Average Density |

Min. Density ASTM C303 |

|

|---|---|---|---|---|---|

| USA ASTM C578 |

Canada CAN/ULC-S701 |

||||

| Regular: 2¼" [57mm] | Type IX | Type 3 | 2 lb/ft³ [32 g/l] | 1.9 lb/ft³ [30 g/l] | 1.8 lb/ft³ [28.8 g/l] |

| Ultra: 3⅛" [79mm] | Type II | Type 2 | 1.5 lb/ft³ [24 g/l] | 1.4 lb/ft³ [22.2 g/l] | 1.35 lb/ft³ [21.7 g/l] |

| Plus: 4¼" [108mm] | Type II | Type 2 | 1.5 lb/ft³ [24 g/l] | 1.4 lb/ft³ [22.2 g/l] | 1.35 lb/ft³ [21.7 g/l] |

| Extra: 4" [102mm] | Type VIII | Type 1 | 1.25 lb/ft³ [20 g/l] | 1.2 lb/ft³ [19 g/l] | 1.15 lb/ft³ [18 g/l] |

| Quad-Deck: 7-12½" | Type VIII | Type 1 | 1.25 lb/ft³ [20 g/l] | 1.25 lb/ft³ [20 g/l] | 1.15 lb/ft³ [18 g/l] |